Digidelta will once again be present at the next edition of Graphispag, which will take place from 24 to 27 May at the Gran Via exhibition centre. Its COO, Armando Mota, gives us a preview of the new items and features of the group’s different brands, the company’s objectives and its expectations in relation to the fair.

Our way of working has undergone major changes as a result of the pandemic. How has Digidelta experienced it?

After two years of pandemic, Digidelta, like many other companies, has had to adapt. Firstly, there is the manufacturing and dispatch part, since the physical presence of people is necessary for production. Then there is the technical support, which needs to remain in place to resolve any machine-related issues. Finally, the sales department, although many things are dealt with remotely, when it comes to closing the deal there is equipment or product samples that need to be shown in person and usually a deal is not closed on a phone call. It has been the management, together with their teams, who have managed to come up with blended working arrangements when necessary.

Digidelta is an official distributor of Mimaki large format digital printers for the Portuguese and Spanish markets and is the manufacturer and distributor of two of its own brands. Do you see significant differences between the Spanish and Portuguese markets?

No, in fact, we are exclusive distributors for Mimaki in Portugal and Spain, and we have a network of local partners who provide this support in both countries. We also carry the Decal and Netscreen brands, of which we are the manufacturer. Netscreen, for the moment, is mainly Portuguese in character, although our intention is to reach the Spanish market, of course. Decal goes far beyond the Iberian market, as we export to more than 50 countries.

We see the Iberian region as a whole and not with the division between Spain and Portugal, although for each region and location we have defined some specific strategies. The Portuguese market is characterised by being dynamic and bold. In terms of consumables there is no difference.

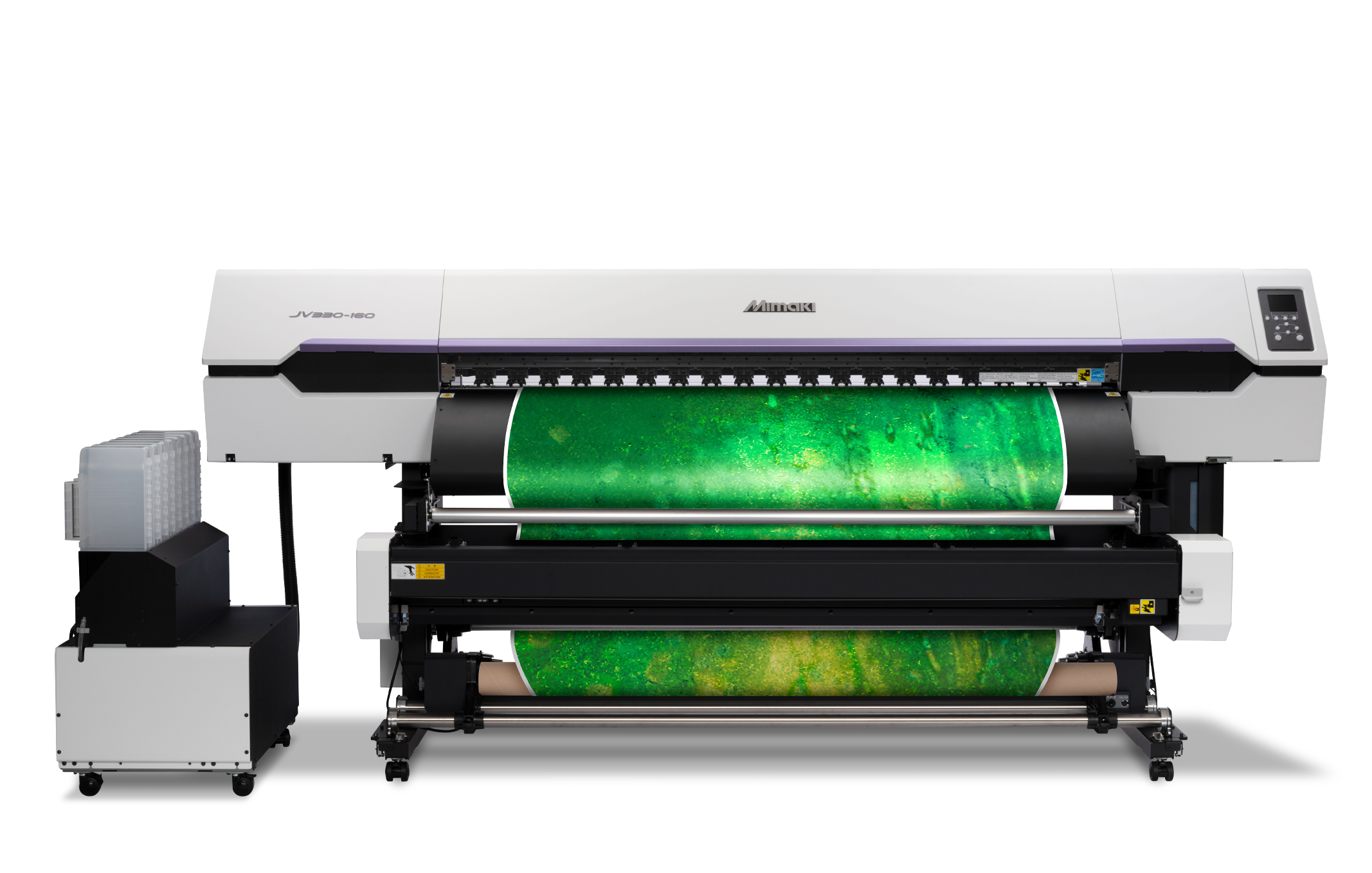

CJV330-160

What innovations will you be presenting at the trade fair?

We will have various new features and products associated with each brand. As far as Mimaki is concerned, we will be bringing three devices from different ranges that were announced at the Mimaki Innovation Days online event. These are the AR series cutting plotters and the solvent digital printing systems, the JV330 and CJV330. We believe that these two machines will be particularly well received in the market for their characteristics.

The units have some unique features that, just when it was thought that solvent units could no longer offer anything new, surprise us once again by showing that this statement is far from true. The evidence is the technology they have, the print quality, the usability, the fact that they allow you to have three rolls of different materials in the back, ready to be used and operate via Wi-Fi.

The vast majority of customers in the area of visual communication are small and medium-sized companies, often with two to four staff members, so the fact that the teams can work unattended thanks to the fact that they can communicate via mobile phones provides a great deal of autonomy to the user.

With the JFX600, the new feature will be two automation systems to automatically feed the unit and also to remove the material from there.

As far as decals are concerned, it is something we had been preparing for some time: Dot Matrix decals, a removable for smooth, non-porous surfaces, with dot adhesive technology, allowing us to meet one of the great needs of retail, which is to produce communication and decoration, mainly applied to shop windows. It can be applied by people with little experience. This is a market that is virtually dominated by one brand. Here we had to be different and we believe we have achieved a more balanced product, with less visible dots, which thanks to its level of transparency helps the decoration to stand out, and not just a film full of dots, as is the case for most of our competitors.

As for Netscreen, we have something that many people talk about, but only a few achieve: flexible LED technology, which is a differentiating factor that shows the world how adaptable this type of technology can become.

They work with sectors such as textiles, packaging, labels and industrial printing. With which sectors do you have the highest turnover?

We work in the visual communication industry as a whole. What for typical advertising companies is large format digital printing, for us is our biggest business.

The textile industry is a very significant market for us. Packaging has huge implications beyond pure business, including everything from the materials that are sold to be glued on a box to machines that print cardboard boxes. In the label business, we have a speciality which is inkjet: this prints with water-based inks, and at the moment we are developing an alternative, because the demand is so great and the lack of material so evident that we are already doing something with a lot of expression, and we intend to go further.

We want to take a step into industrial printing with IOT systems. In fact, with Mimaki this is no longer something new, as we introduced the JFX600 machine. We will have two automated systems automatically feeding the unit and removing the material from there. Mimaki units, with these integrated automation systems, can perform a variety of applications on pieces or sets of pieces undergoing transformation.

From the point of view of the printing industry, what can LED UV printing technology bring to the table?

I recently read a report which mentioned that the digital printing market will continue to grow and the trend of the future will be UV LED. One of the main advantages of UV LED is its capability, as the inks allow printing on a variety of materials, with almost no limitations. Of course, there are certain surfaces, which due to the treatments applied to them or the type of material, need to be primed beforehand, and many equipment designs have already succeeded in providing an answer to these situations. This freedom to print on any material means a significant advantage that others do not have.

The second advantage is that any material can be processed without subjecting it to temperatures. This means we have a wider range of materials to print on, we eliminate temperature sensitivity and, last but not least, print quality, where Mimaki has more versatile inks that are suitable for both rigid and flexible applications, allowing us to customise according to each of our customer’s needs. This freedom can only be achieved with UV, as no other technique has the breadth of qualities offered by UV technology.

What do your customers demand most?

The customer is generally more demanding in terms of quality, less able to deal with error, with less viable products and demands more certifications. In the case of decals, there is a trend to demand plasticiser-free materials, as there is greater concern for the environment. The brand will make its major contribution with its range of PVC-alternative self-adhesive materials for the area of visual communication.

UV printing has been the answer and is increasingly taking up more and more space in terms of decision-making, and will continue to do so.

JV330-160

Have you noticed any changes in the last two years?

The situation generated by the pandemic has accelerated some attitudes. People are looking for more quality time and there is greater environmental awareness. At Digidelta we have a lot to say about it, as I have already mentioned, thanks to Mimaki equipment. They are able to work unattended, during the night, taking advantage of idle hours and updating the user on their status.

In addition, to accompany the more environmental requirements, we have the PVC -free range of decal materials, free of plasticisers, reducing the carbon footprint and providing better processing conditions after use, something that has changed in recent years and to which, fortunately, we have responded.

What challenges do you see facing the sector in the coming years?

The big challenge, after all, is to overcome the crisis caused by the pandemic. We now have a war which, whether we like it or not, has a major impact and raises problems that we will have to deal with, such as inflation and shortages of raw materials. The biggest challenge is to try to overcome these challenges we are experiencing now.

The big challenge is to deal with the lack of investor confidence. It is not exclusive to this sector, but we are aware that when there is a crisis, one of the most seriously affected sectors is visual communication. However, if there is one thing this pandemic situation has taught us, it is that no matter what happens, if there is no communication it makes matters worse, and brands themselves have already realised this.

The goal is to maintain that vision for the whole market in view of the need to renew its existing machinery and to continue in this position because, as a rule, when there is a crisis, it is one of the things that is most affected. Furthermore, we are showing the industry that this is possible and that it can happen by using our own financial tools: Digirent and Printplan, with Digirent at the fore in this case. The purchase of consumables allows people to have equipment at virtually zero cost, depending on their consumption volume. This is our way of contributing to making these challenges more manageable.

What does attending a trade fair like Graphispag mean to you?

In our case participating in Graphispag is not up for discussion. This market segment is particularly important for us with regard to Mimaki, decals and Netscreen. This year, following on from last year, when we had everything much more focused on the textiles market, we expanded our showroom, which is now complete with all types of equipment and consumables on display, allowing any user to check it out hands-on.

The market in Catalonia is one that has known us for many years, but I admit that they always see us as a company that is geographically far away. Although we work a lot as partners, we have support centres in Madrid and Barcelona, so Graphispag will serve to establish a presence close to them, but also to inform potential and existing customers that this participation can be extended throughout the year.

This year’s edition will be very special, as in addition to all the new products and features, it will also serve to reinforce the message that we are not only present at this time, but all year round.

Cristina Benavides, Graphispag contributor